What Is Aggregate and Why Is It Used in Concrete?

In its simplest form, concrete is the combination of cement and aggregate. The cement is added to the aggregate in its fluid form. As the cement hardens, it binds with the aggregates to produce an extremely tough and resilient material we know as concrete.

But what is aggregate exactly? Well, it can be many different things. Various materials are used as aggregate in concrete, and each one affects the quality of the concrete in various ways. In this article, discover the most common types of aggregate and how they affect the finished product.

Need concrete for your project? Place an order today with our team on 0800 859 5371 !

What is aggregate?

Aggregate is a collection of inert granular material that comprises as much as 60% to 80% of a typical concrete mix. There are many different types of aggregate commonly found in concrete. These include:

- Sand

- Gravel

- Recycled concrete

- Glass

- Limestone

- Granite

These materials are classed as aggregate when they have been crushed down into fine particulates. They are further classified as either ‘coarse aggregate’ or ‘fine aggregate’ based on the following characteristics:

- Coarse aggregates have a diameter of between 9.5mm – 37.5mm

- Fine aggregates have a diameter of less than 9.55mm

Why do we use aggregate in concrete?

Aggregate provides much of the strength, thermal and elastic properties of concrete, as well as dimension and volume stability. Including aggregate in the mix can also control shrinkage and prevent cracking.

A specific aggregate (or combination of aggregate) is selected for its durability, strength, workability and ability to receive finishes. And to go even further, changes in the size, weight, moisture content and gradation of each aggregate can also alter the characteristics of the concrete.

What is grading and why is it important to concrete strength?

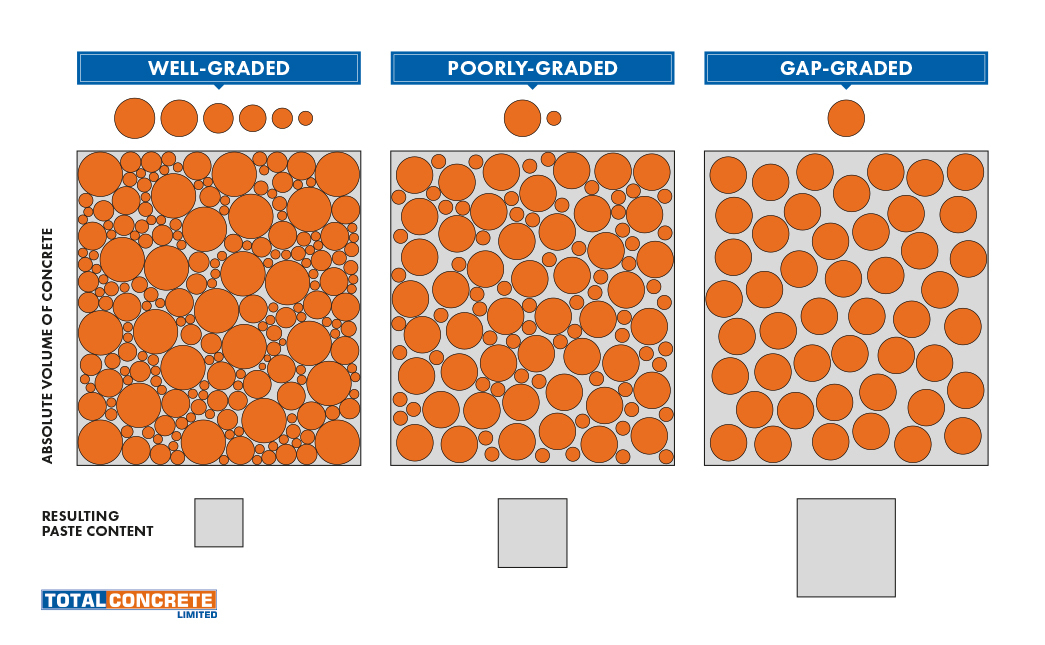

Aggregate gradation is a method of utilising all available space within the concrete. Aggregate grades determine how dense or sparse the aggregate is. There are three typical gradings given to aggregates. These are:

Well Graded

This is the top grade, indicating a tightly packed field of many different particle sizes.

Poorly Graded

This grade indicates little variation in size. Because they are all equal size, the particles are unable to take advantage of all the available space, leaving many large voids in the concrete.

Gap Graded

This grade indicates a combination of large and small particles, with medium-sized particles missing. The small particles are tightly packed in the voids left between the large particles. Though they are tightly packed, the contrast in size doesn’t provide the same uniformity as well-graded aggregate.

We know this might be a bit confusing, but don’t get ‘grading’ confused with ‘concrete grades’. The term ‘grading’ related to how the aggregates are used in the concrete mixture. A ‘concrete grade’ is a type of concrete.

To learn more see our Concrete Grades Guide.

The more closely packed the particles of the aggregate are, the greater its strength and therefore the greater the strength of the concrete. Poorly-graded concretes require excessive amounts of cement paste to fill the voids.

Well-graded aggregate is best, however, aggregates graded to maximum density can give the concrete a harsh texture.

At Total Concrete, we’re committed to supplying you with the perfect type and volume of concrete for your project. Whether you’re taking on a small domestic project or you need concrete for a large commercial job, we will supply exactly what you need, precisely when you need it. Try our concrete calculator to find out how much concrete your project needs.

Order and we’ll deliver your ready-mix concrete straight to your door. Alternatively, take advantage of our on-site-mixed concrete service. We’ll travel to you and mix your concrete on site. This ensures you get a fresh batch mixed to the exact proportions you need.

Call us on 0800 859 5371 to place your order!

We serve customers in Woking, Surrey, Guildford and the surrounding areas. Get in contact with our team to find out how we can help you.

Trade Zone

Trade Zone