Concrete Slump Tests – Measuring the Workability of Concrete

Concrete slump tests are a routine procedure carried out on a fresh concrete mix to determine its consistency before it is poured. The test is incredibly simple and is a great, quick method to check that multiple batches of the same concrete are consistent. Let’s take a look at the concrete slump test in more detail.

- Place an order and book your concrete delivery with our team! Call us on 0800 859 5371 for a quote!

What is the concrete slump test?

Freshly mixed concrete — that is soon to be poured — should meet a certain standard before being used as part of a construction project. A concrete slump test measures the consistency of a concrete batch to see how easily the concrete will flow. The test not only observes consistency between batches, but it also identifies defects in a mix, giving the operator a chance to amend the mix before it is poured on site.

By measuring the overall ‘slump’ of the concrete, you can tell whether or not the water-cement ratio is too high, and whether a mix will have high workability or not.

Why use a concrete slump test?

The main reason to perform the test is to ensure batches of the same concrete are of constant quality and strength. The more water is added to a mix, the weaker the concrete gets. If customers require a higher workability/more flowing concrete ( a higher slump result) we need to increase the cement content to ensure the concrete still reaches its target strength. This test is just one of the ways we ensure the quality of our concrete. Water is the enemy when it comes to concrete strengths.

Looking for high-quality concrete for your project?

Concrete SuppliersHow do you carry out a slump test?

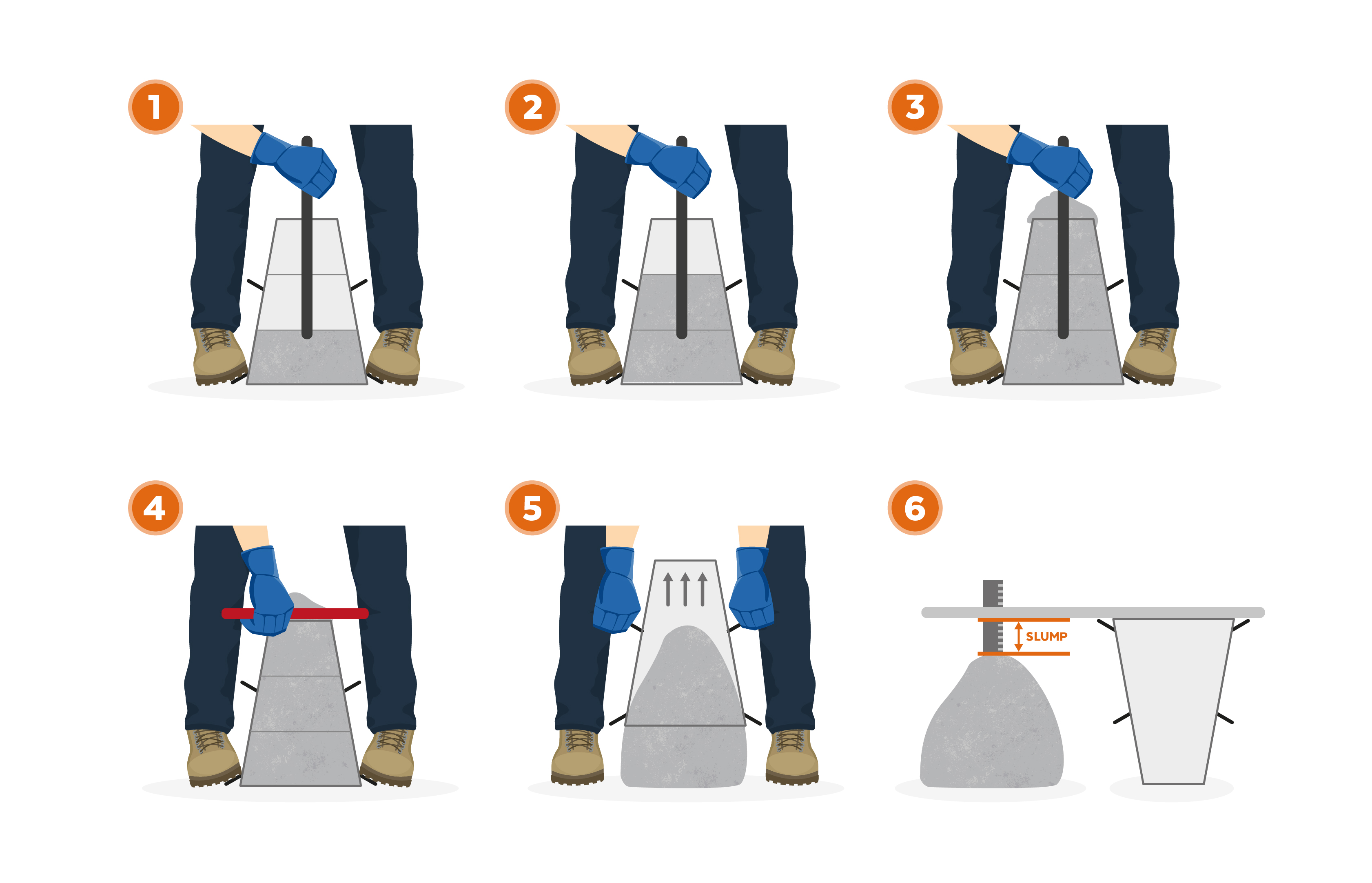

This easy test is carried out in just seven stages, using a slump cone, a steel rod, and a measuring stick. Here’s how you carry out the test:

- 1. Place the cone on a flat, smooth, horizontal surface and stand on the footholds either side to ensure the cone is planted firmly on the ground

- 2. Fill the cone in three layers, using the steel tamping rod to compact — or tamp — the concrete after each layer in an even, uniform manner (this should be done 25 times per layer).

- 3. Once the cone is filled, remove any overflowing concrete from the top, making sure the concrete fills the cone exactly to the top level. Remove any spilled concrete from the base of the cone, too.

- 4. Lift the cone vertically, using a slow and steady motion until the cone is clear of the concrete. Place the cone upside down on the surface next to the concrete.

- 5. The concrete will subside — or slump. To measure the slump, place the steel rod across the top of the upturned cone so it overhangs the concrete.

- 6. Now, measure from the rod down to the top of the slump. The level of slump is measured to the nearest 5mm.

Results of the slump test

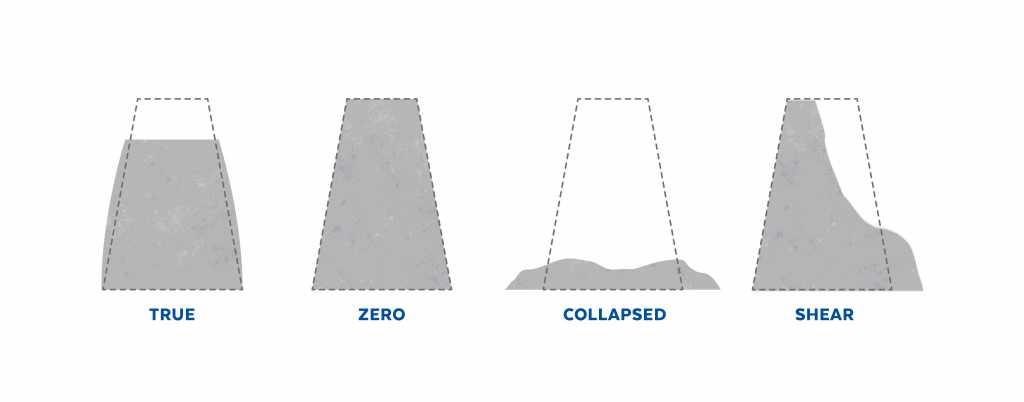

Depending on the water-cement ratio of the mix, the concrete slump will fall under one of four categories:

- True slump — the concrete largely retains its cone shape, demonstrating that the mix is cohesive and its workability isn’t too high.

- Zero slump — the concrete retains its shape completely. This shows that the mix is very dry (this kind of concrete is best used in road construction).

- Shear slump — the top half of the concrete subsides dramatically, leaning to one side, meaning the mix has workability but low cohesion. The mix may have too much water content and can be retested after being amended

- Collapse — the mix doesn’t retain its shape at all and completely collapses. This means the water-cement ratio is too high and needs to be fully amended.

At Total Concrete, we can create a wide range of concrete mixes at our state–of–the–art batching plant, including ready mix concrete and specialty mixes.

Our knowledgeable personnel can advise on the right mix for your commercial, industrial or domestic project, and will ensure that your mix meets your every construction requirement. To order your concrete direct to your site, simply contact us today.

Trade Zone

Trade Zone